From Spin Cycle to Second Chance

They arrive rattling, leaking, or completely silent. Most people would call them rubbish. We call them opportunity. Over the past three months, thirteen washing machines have come through our doors, proving that “broken” is often just the beginning of the story.

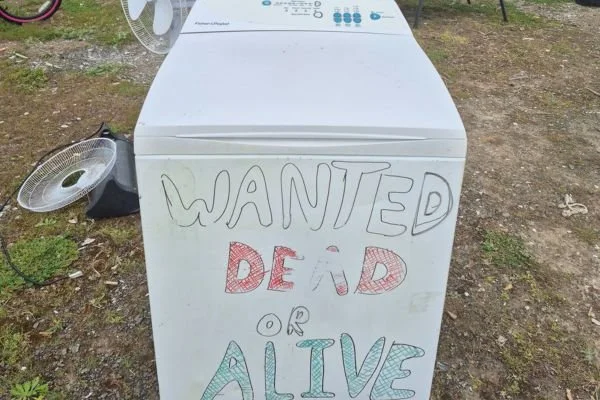

On any given day at our resource recovery centre, the washing machines arrive like tired marathon runners at the finish line. Some limp in with a groan and a rattle. Others arrive in dignified silence, having simply decided they’ve done enough loads for one lifetime.

In the past three months alone, thirteen washing machines have rolled through our doors.

Four of them are back out in the world, humming happily in new homes after a bit of expert TLC. The other nine? They didn’t go to waste. Not even close.

This is what the circular economy looks like when you zoom in.

Each machine tells a story. A seized pump becomes a spare for the next repair job. A motor gets carefully removed and shelved for future use. Wiring, switches, valves — all sorted, saved, and catalogued. Even the outer shells and frames head to metal recycling. And the drums? The glorious stainless-steel drums become some of the most popular planters in town. You haven’t truly seen second life creativity until you’ve spotted tomatoes growing out of a former spin cycle.

Nothing is random. Nothing is wasted.

We source and fit new circuit boards. Our team tests every appliance that leaves as “going.” They’re checked, tagged, and compliant, ready for round two in a new laundry. For the buyer, it’s a bargain. For the planet, it’s a win. For us, it’s a small but powerful reminder that repair still matters.

This work creates local employment. It keeps valuable materials out of landfill. It stretches the life of goods that still have plenty to give. It proves that “broken” doesn’t mean “finished” — it just means “needs the right hands.”

There’s something deeply satisfying about watching a machine that was destined for the scrap heap spin back into service. It’s practical, yes. But it’s also hopeful.

Because this isn’t theory. It’s not a policy document or a buzzword.

It’s thirteen washing machines. Four second chances. Nine carefully harvested for parts. A row of planter drums. Shelves of spares. Skilled hands at work.

It’s the circular economy, in motion, every single day.

By Tracey Bell